Laser

Laser

Yes, I know I skipped September, it is still in the works but having digital camera issues. I can't seem to get good closeups. Yet. I will.

This issue is all about finding the distance from one point to another. Several methods are discussed:

Laser

Laser

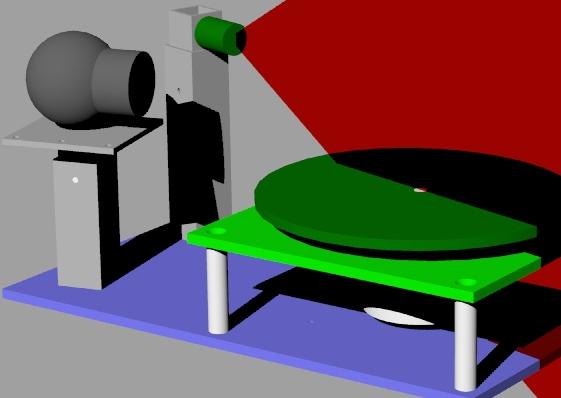

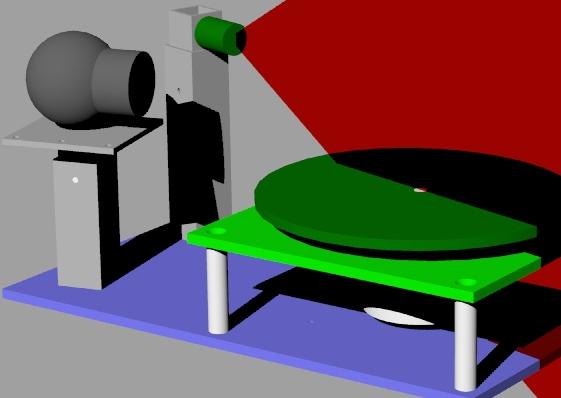

I've had the joy of working on a really interesting project with a real 3D CAD expert. Mostly I helped with some math and spewed out ideas, but the simplicity and the results are astounding. The project is a laser 3D scanner built for much less than any commercial unit.

The basic idea is probably best shown by these pictures from http://www.cyberg8t.com/pendragn/actlite.htm (which is no longer, but has been cached)

|

- |  |

= |  |

And then the position of the laser line is used to calculate the depth of the object.

Because the Laser and Motor have to be timed and driven together both use the parallel port data lines. Only 3 of the 8 data lines are needed:

Also the software interface for the parallel port is easy to use with Jan Axelsons Inpout32.dll (available at www.lvr.com).

Routines are:

Laser True

Wait 0.3

ezVidCap1.SaveDIB ("c:\temp\laserOn.bmp")

Picture2.Picture = LoadPicture("c:\temp\laserOn.bmp")

Laser False

Wait 0.3

ezVidCap1.SaveDIB ("c:\temp\laserOff.bmp")

Picture1.Picture = LoadPicture("c:\temp\laserOff.bmp")

Step_Clock

|

This routine relies on the ezvidCap component from Ray Mercer

http://www.martin2k.co.uk/vb6/tips/x4.php

And a little easy port IO code:

Private Sub Step_Clock()

Out Val("&H" + "0378"), 1: Wait 0.1

Out Val("&H" + "0378"), 0: Wait 0.1

End Sub

Private Sub Laser(switch As Boolean)

If switch = False Then Out Val("&H" + "0378"), 0

If switch = True Then Out Val("&H" + "0378"), 8

End Sub

' Set the pixel color values.

For Y = 0 To Picture1.ScaleHeight - 1

For X = 0 To Picture1.ScaleWidth - 1

With pixels(X, Y)

.rgbRed = Abs(CInt(.rgbRed) - pixels2(X, Y).rgbRed)

.rgbGreen = Abs(CInt(.rgbGreen) - pixels2(X, Y).rgbGreen)

.rgbBlue = Abs(CInt(.rgbBlue) - pixels2(X, Y).rgbBlue)

If (.rgbRed > filter) And

(.rgbGreen > filter) And

(.rgbBlue > filter) Then

.rgbRed = 0

.rgbGreen = 0

.rgbBlue = 0

Else

.rgbRed = 255

.rgbGreen = 255

.rgbBlue = 255

End If

End With

Next X

Next Y

|

This routine is adapted from the book Visual Basic(r) Graphics Programming: Hands-On Applications and Advanced Color Development, 2nd Edition by Rod Stephens for image processing and edge detection.

Angle = (Frame / LastFrame) * Pi * 2

For PicY = 0 To Picture5.ScaleHeight - 1

Z = PicY

For PicX = 0 To Picture5.ScaleWidth - 1

R = (Picture5.ScaleWidth / 2) - PicX

R = R / 0.5

With pixels(PicX, PicY)

RetR = .rgbRed

If RetR = 0 Then

X = R * Cos(Angle)

Y = R * Sin(Angle)

Print #1, X; ","; Y; ","; Z

End If

End With

Next PicX

Next PicY

|

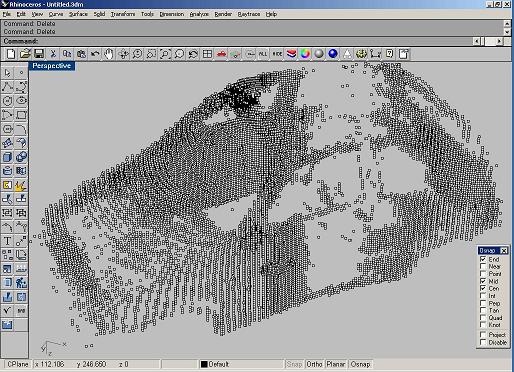

And the

result is a "point cloud" that describes your subject. Additional software

will be added to process the points into lines or faces, smooth and reduce

the complexity of the image.

And the

result is a "point cloud" that describes your subject. Additional software

will be added to process the points into lines or faces, smooth and reduce

the complexity of the image.

Now, this process can, and has to some degree, been done with a microcontroller. Here are the potential problems and how they are avoided:

Sonar

Sonar

This simple sonar ranging device eliminates a lot of the usual discrete components by executing complex functions in the software of the microcontroller. Several times per second, the it generates a few cycles (about 8) of a 40 kHz square wave on an output that directly drives the transmitter element. It then begins counting "ticks" (fast program loops) which will accumulate until it either detects a response from the 567 tone decoder or a maximum period has expired. Immediately following the 40 kHz burst, the output of the 567 chip is ignored for a short time. This is because the 567 will detect the burst, and the transmitter element will continue to ring or resonate for a short time. The 567 tone decoder chip is a phase locked loop designed to detect when the input frequency is within a certain pass-band. The passband or detection range is determined by the values of the discrete components connected to it. This makes it very easy to use. The 567 has been around for many years, it's cheap, and very useful. Ultrasonic sound waves emitted from the transmitter element travel through the air, hit an object and bounce back to the unit where the receiver element detects them. The output of the receiver is amplified and sent into the 567 chip. The 567 chip drives its output low when it detects the reflected 40 kHz signal. It will react to all reflections so it may produce more than one output pulse, but this version of the code will only register the first one. Several readings per second are averaged and a value proportional to the detected distance is sent out via a serial line. The pictures show this connected to a serial LCD. Be aware that the value is for demonstration purposes only and not been scaled to any actual units of length like feet or centimeters. You would have to add your own code or lookup table to display specific units of measure.

The program is designed to run in different modes. The dip-switches are used to select the mode of operation, such as "normal pulse o/p", "continuous tone o/p" with is used for tuning the 567 for best detection, "binary serial o/p", "ascii serial o/p", etc.

The processor has a "serin" pin which can be used as a control input from another processor. Through this pin, it could receive instructions but this block of code is unfinished and should be tailored to your application. If selected, nothing will happen, however, it would be a simple matter to add code that would allow the input to act as a "logic enable" or to accept various serial commands. Alternatively, the serin pin could be programmed as some sort of o/p.

The "serout"

pin is used to output the range test results. In ascii o/p mode, the results

are sent with the LCD-Backpack's value for the "I" instruction (#254) value

first that instructs a backpack-LCD or serial-LCD to enter "instruction mode".

The next byte sent is the address of line2 (#192) which sets the cursor of

the LCD to the start of line 2. Then three ascii digits are sent, MSD first,

center digit, LSD last. If the result is a BCD number less than 3 digits,

spaces are sent to clear those digits from the display. In binary o/p mode,

the straight binary test result is sent.

The transmitter is a 40kHz transducer from Digikey, part# P9895-ND.

The receiver is a 40kHz transducer from Digikey, part# P9890-ND.

The PCB design uses several surface mount components. It saves a lot of hole drilling and lead bending and clipping. Also, assemblies end up smaller, better looking and easier to modify or service. Soldering surface mount (especially the larger variants) is ease

;Filename: SONAR1.SRC

;Created: MAY.4.97

;Last Modified: MAY.4.97

;Language: PARALLAX assembler

;PCBname: SONAR1.JOB

;Schematic: SONAR1.SCH

;Processor: PIC16C71

;Written By: William J. Boucher

;

;DESCRIPTION:

;

;This program is designed to run the mini robot sonar1 module as a

;rangefinder sensor. It generates a 40kHz pulse, the measures the time

;until an echo is detected. The dip-switches are used to select different

;modes of operate, such as "normal pulse o/p", "continuous tone o/p"

;for tuning purposes, "binary serial o/p", "ascii serial o/p", etc.

;This sensor is intended for use in miniature robot applications.

;The transmitter is a 40kHz transducer from Digikey, part# P9895-ND.

;The receiver is a 40kHz transducer from Digikey, part# P9890-ND.

;The processor has a "serin" pin which can be used as a control input from

;another processor. Through this pin, it could receive instructions.

;Also, the serin pin could be programmed as some sort of o/p.

;The "serout" pin is used to output the range test results.

;In ascii o/p mode, the results are sent with the "I" (254) value first

;which instructs a Stamp-based LCD to enter "instruction mode".

;The next byte sent is the address of line2 "192" which sets the cursor

;of the LCD to the start of line 2. Then three ascii digits are sent,

;MSD first, center digit, LSD last. If the result is a BCD number less

;than 3 digits, spaces are sent to clear those digits from the display.

;In binary o/p mode, the straight binary test result is sent.

;The serial data is programmed to have a bit width of 0.104ms (9600baud).

;The data words are sent with:

;- a single high start bit

;- inverted data, LSB first

;- a single low stop bit.

;

;TASKLIST 1/ Initialize registers & variable names & inputs/outputs.

; 2/ Read dipswitches to determine mode.

; 3/ Enter mode.

; 4/ Calculate/update variables as required.

; 5/ Send 8 bit result data in format selected.

; 6/ Repeat at step 2.

;

;----------------------------------------------------------------------------

DEVICE PIC16C71,HS_OSC,WDT_OFF,PWRT_ON,PROTECT_OFF

ID 'SOR1' ;FIRST 2 & LAST 2 CHARS OF FILENAME

;----------------------------------------------------------------------------

;EQUATES:

;

LINE1 = 128 ;LCD LINE1 START ADDRESS

LINE2 = 192 ;LCD LINE2 START ADDRESS

I = 254 ;LCD INSTRUCTION COMMAND

CLRLCD = 1 ;LCD CLEAR INSTRUCTION

XMIT1 = 5.2 ;PIN 1 OF TRANSMITTER

XMIT2 = 5.3 ;PIN 2 OF TRANSMITTER

SERIN = 6.0 ;SERIAL INPUT PIN

SEROUT = 6.1 ;SERIAL O/P PIN

DETECT = 6.2 ;INPUT FROM OUTPUT OF LM567 TONE DETECTOR

DIPSW1 = 6.4 ;DIP SWITCH 1

DIPSW2 = 6.5 ;DIP SWITCH 2

DIPSW3 = 6.6 ;DIP SWITCH 3

DIPSW4 = 6.7 ;DIP SWITCH 4

TIMER = 1 ;TMR0 ON BOARD TIMER

TIMERVAL40K = 228 ;VALUE CONTROLS LOOP FREQ TO 40kHz

;226=38.5kHz

;224=35.2kHz

;31=5.45kHz

TIMERFLAG = 11.2 ;TIMER0 OVERFLOW FLAG

XMITA = 00000100B

XMITB = 00001000B

XMITLOW = 0

XMITENABLE = 11110011B

XMITDISABLE = 11111111B

;----------------------------------------------------------------------------

;VARIABLE STORAGE

ORG 0CH ;SET TO START OF GENERAL PURPOSE RAM

DELAYCOUNTER1 DS 1

DELAYCOUNTER2 DS 1

DELAYCOUNTER3 DS 1

SERINDATA DS 1

SEROUTDATA DS 1

BIN DS 1

R1 DS 1

R2 DS 1

COUNTER1 DS 1

COUNTER2 DS 1

BITCOUNTER DS 1

TEMP DS 1

TABLEENTRY DS 1

TABLEVALUE DS 1

RANGERESULT DS 1

RANGEAVERAGE DS 1

RANGEDATAH DS 1

RANGEDATAL DS 1

RESULTCOUNTER DS 1

STATS DS 1

;----------------------------------------------------------------------------

ORG 0

;INITIALIZE VARIABLES

INITIALIZE CLR 8 ;TURN OFF A2D CONVERTER & SET CLKRATE

;& SET TO CHANNEL 0 <3:0>

SETB RP0 ;SET RP0 TO UPPER REGISTER BANK

MOV 1,#00000000B ;SET OPTION REG. RB-PULL-UPS ON

; & TIMER PRESCALER TO 1:2

; & ASSIGN PRESCALER TO TIMER

MOV 8,#3 ;SET PORT1 INPUTS AS DIGITAL

;MOV RA,#XMITDISABLE ;SET PORT RA DATA DIRECTIONS

MOV RA,#XMITENABLE ;SET PORT RA DATA DIRECTIONS

MOV RB,#11110101B ;SET PORT RB DATA DIRECTIONS

CLRB RP0 ;SET RP0 TO LOWER REGISTER BANK

CLRB SEROUT

CLR STATS

MOV RESULTCOUNTER,#8

;----------------------------------------------------------------------------

MAINLOOP MOV TEMP,RB

NOT TEMP

SWAP TEMP

AND TEMP,#00001111B

MOV W,TEMP

JMP PC+W

JMP MODE0

JMP MODE1

JMP MODE2

JMP MODE3

JMP MODE4

JMP MODE5

JMP MODE6

JMP MODE7

JMP MODE8

JMP MODE9

JMP MODE10

JMP MODE11

JMP MODE12

JMP MODE13

JMP MODE14

;----------------------------------------------------------------------------

;MODE15:

MODE15 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE14:

MODE14 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE13:

MODE13 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE12:

MODE12 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE11:

MODE11 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE10:

MODE10 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE9:

MODE9 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE8:

MODE8 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE7:

MODE7 JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE6:USE SERIN COMMANDS TO CONTROL MODULE

MODE6 CALL RECEIVE

CJE SERINDATA,#'1',MODE6A

JMP MAINLOOP

MODE6A CALL RANGETEST

MOV SEROUTDATA,RANGERESULT

CALL TRANSMIT

JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE5:SERIN IS LOGIC ENABLE FOR MODE4

MODE5 JB SERIN,MODE4

JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE4:GENERATE CONTIUOUS 40kHz TRANSMISSION FOR CALIBRATION PURPOSES

MODE4 ;CALL XMITON ;ENABLE TRANSMITTER DRIVER PINS

JNB TIMERFLAG,$ ;WAIT HERE TIL TIMER RUNS OUT

;TIMERVALUE SET TO GIVE 40kHz

;NOP ;FREQUENCY FINE TUNE

MOV TIMER,#TIMERVAL40K ;LOAD TIMER0

CLRB TIMERFLAG ;CLEAR TIMER0 OVERFLOW FLAG

JB XMIT1,MODE4A ;TEST PRESENT O/P STATE

NOP

MOV RA,#XMITA ;FLIP O/P STATE

JMP MAINLOOP

MODE4A MOV RA,#XMITB ;FLIP O/P STATE

JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE3:SERIN IS LOGIC ENABLE FOR MODE1

MODE3 JB SERIN,MODE1

JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE2:SERIN IS LOGIC ENABLE FOR MODE0

MODE2 JB SERIN,MODE0

JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE1:CONTINUOUS RANGING - SENDS DATA IN BINARY VIA SEROUT AT 9600 BAUD

MODE1 CALL RANGETEST

MOV SEROUTDATA,RANGERESULT

CALL TRANSMIT

JMP MAINLOOP

;----------------------------------------------------------------------------

;MODE0:CONTINUOUS RANGING - SENDS DATA TO STAMP-LCD VIA SEROUT AT 9600 BAUD

MODE0 JB STATS.0,MODE0RUN

SETB STATS.0 ;INDICATE LCD INTIALIZED

CALL POWERUPDELAY ;WAIT FOR LCD TO INITIALIZE

MOV SEROUTDATA,#I ;LOAD "INSTRUCTION" VALUE

CALL TRANSMIT

MOV SEROUTDATA,#CLRLCD

CALL TRANSMIT

CALL DELAY5MS

;WRITE TITLE ON LCD LINE1

MOV SEROUTDATA,#I ;LOAD "INSTRUCTION" VALUE

CALL TRANSMIT ;SEND VALUE TO LCD

MOV SEROUTDATA,#LINE1 ;LOAD ADDRESS FOR CURSUR

CALL TRANSMIT ;SEND VALUE TO LCD

MOV COUNTER2,#10 ;LOAD NUMBER OF TABLE ENTRIES TO READ

MOV TABLEENTRY,#10 ;LOAD TABLE ADDRESS TO READ

CALL MODE0A ;PRINT LINE ON DISPLAY

;WRITE TITLE ON LCD LINE2

MOV SEROUTDATA,#I ;LOAD "INSTRUCTION" VALUE

CALL TRANSMIT ;SEND VALUE TO LCD

MOV SEROUTDATA,#LINE2 ;LOAD ADDRESS FOR CURSUR

CALL TRANSMIT ;SEND VALUE TO LCD

MOV COUNTER2,#10 ;LOAD NUMBER OF TABLE ENTRIES TO READ

MOV TABLEENTRY,#20 ;LOAD TABLE ADDRESS TO READ

CALL MODE0A ;PRINT LINE ON DISPLAY

JMP MODE0RUN

MODE0A CALL READTABLE ;GET TABLE VALUE

MOV SEROUTDATA,TABLEVALUE ;LOAD VALUE TO SEND

CALL TRANSMIT ;SEND VALUE TO LCD

INC TABLEENTRY

DJNZ COUNTER2,MODE0A

RET

MODE0RUN CALL RANGETEST ;RUN DISTANCE MEASUREMENT TEST

CALL RANGEAVER

MOV BIN,RANGEAVERAGE ;LOAD RANGE TEST RESULT TO CONVERT

CALL BIN2BCD ;CONVERT BINARY RESULT TO BCD

MOV SEROUTDATA,#I ;LOAD "INSTRUCTION" VALUE

CALL TRANSMIT ;SEND VALUE TO LCD

MOV SEROUTDATA,#LINE2+7 ;LOAD ADDRESS FOR CURSUR

CALL TRANSMIT ;SEND VALUE TO LCD

MOV TABLEENTRY,R1 ;LOAD 1'st (MSD) DIGIT TO SEND

AND TABLEENTRY,#00001111B

CALL READTABLE ;CONVERT NUMBER TO ASCII

MOV SEROUTDATA,TABLEVALUE

CALL TRANSMIT ;SEND VALUE TO LCD

MOV TABLEENTRY,R2 ;LOAD 2'nd DIGIT TO SEND

SWAP TABLEENTRY

AND TABLEENTRY,#00001111B

CALL READTABLE

MOV SEROUTDATA,TABLEVALUE

CALL TRANSMIT ;SEND VALUE TO LCD

MOV TABLEENTRY,R2 ;LOAD 3'rd (LSD) TO SEND

AND TABLEENTRY,#00001111B

CALL READTABLE

MOV SEROUTDATA,TABLEVALUE

CALL TRANSMIT ;SEND VALUE TO LCD

JMP MAINLOOP

;----------------------------------------------------------------------------

;TRANSMIT: SENDS AN 8-BIT BYTE SERIALLY OUT THROUGH THE SEROUT PIN

TRANSMIT ;CLC ;CLEAR CARRY

STARTBIT SETB SEROUT ;BEGIN THE START BIT

CALL BITDELAY ;DELAY PRODUCES BIT WIDTH FOR 9600 BAUD

SENDDATA MOV BITCOUNTER,#8 ;INITIALIZE THE SERIAL DATA BIT COUNTER

READDATA RR SEROUTDATA ;READ STATE OF BIT AND SEND INVERTED

JC SENDA0 ;IF DATA BIT=1, SEND A 0

SENDA1 SETB SEROUT ;SEND A 1

JMP WAITABIT ;GO TO WAITABIT

SENDA0 CLRB SEROUT ;SEND A 0

WAITABIT CALL BITDELAY ;

DJNZ BITCOUNTER,READDATA ;WERE ALL BITS SENT YET?

STOPBIT CLRB SEROUT ;CLEAR SEROUT TO BEGIN STOP BIT

CALL BITDELAY ;

;CLRB SEROUT ;END STOP BIT

;RET

;----------------------------------------------------------------------------

;WORD DELAY; 20 X 1 BIT = 2.083ms @ 20MHz

WORDDELAY MOV DELAYCOUNTER2,#14

WDA MOV DELAYCOUNTER1,#255

DJNZ DELAYCOUNTER1,$

DJNZ DELAYCOUNTER2,WDA

RET

;----------------------------------------------------------------------------

;DELAY5MS: 5ms DELAY, USED AFTER SOME LCD INSTRUCTIONS

DELAY5MS MOV DELAYCOUNTER2,#33

D5MSA MOV DELAYCOUNTER1,#255

DJNZ DELAYCOUNTER1,$

DJNZ DELAYCOUNTER2,D5MSA

RET

;----------------------------------------------------------------------------

;DELAY100MS: 100ms DELAY, USED AFTER SOME LCD INSTRUCTIONS

DELAY100MS MOV DELAYCOUNTER3,#3

D100MSA MOV DELAYCOUNTER2,#217

D100MSB MOV DELAYCOUNTER1,#255

DJNZ DELAYCOUNTER1,$

DJNZ DELAYCOUNTER2,D100MSB

DJNZ DELAYCOUNTER3,D100MSA

RET

;----------------------------------------------------------------------------

;RECEIVE:GETS A BYTE FROM SERIN AT 9600 BAUD - NOT DONE YET

RECEIVE CLR SERINDATA

RET

;----------------------------------------------------------------------------

;NOTE: BIT DELAYS FOLLOWING PRODUCE 9600 BAUD RATE w/20MHz XTAL

;;---------------------------------------------------------------------------

;TIME DELAY; 1 BIT = 104.166us @ 20MHz

BITDELAY MOV DELAYCOUNTER1,#172

DJNZ DELAYCOUNTER1,$

RET

;----------------------------------------------------------------------------

;;TIME DELAY; 1 BIT = 0.104ms @ 20MHz

;HALFBITDELAY MOV DELAYCOUNTER1,#86

; DJNZ DELAYCOUNTER1,$

; DJNZ DELAYCOUNTER1,HBDELAYA

; RET

;----------------------------------------------------------------------------

;POWERUPDELAY; 1s @ 20MHz

POWERUPDELAY MOV DELAYCOUNTER3,#250

PUDA MOV DELAYCOUNTER2,#255

PUDB MOV DELAYCOUNTER1,#26

DJNZ DELAYCOUNTER1,$

DJNZ DELAYCOUNTER2,PUDB

DJNZ DELAYCOUNTER3,PUDA

RET

;----------------------------------------------------------------------------

;Binary number to be converted starts out stored like this:

;

; binary low byte

; BIN

; ########

;

;BCD result ends up stored like this:

;

;R0 = digit5 (MSD) in lower nibble:digit4

; R1 : R2 LSD

; dig3 : dig2 dig1

; 0000 #### : #### ####

BIN2BCD CLC ; clear the carry bit

MOV COUNTER1,#8

CLR R1

CLR R2

LOOP8 RL BIN

RL R2

RL R1

DJNZ COUNTER1,ADJDEC

RET

ADJDEC MOV FSR,#R2

CALL ADJBCD

MOV FSR,#R1

CALL ADJBCD

JMP LOOP8

ADJBCD MOV W,#3

ADD W,INDIRECT

MOV TEMP,W

SNB TEMP.3 ; test if result > 7

MOV INDIRECT,W

MOV W,#48 ;OR #30H

ADD W,INDIRECT

MOV TEMP,W

SNB TEMP.7 ; test if result > 7

MOV INDIRECT,W ; save as MSD

RET

;----------------------------------------------------------------------------

RANGETEST MOV TIMER,#TIMERVAL40K ;LOAD TIMER0

CLRB TIMERFLAG ;CLEAR TIMER0 OVERFLOW FLAG

MOV COUNTER1,#10 ;NUMBER OF HALFCYCLES TO XMIT

;CALL XMITON ;ENABLE TRANSMITTER DRIVER PINS

RTA JNB TIMERFLAG,$ ;WAIT HERE TIL TIMER RUNS OUT

;TIMERVALUE SET TO GIVE 40kHz

MOV TIMER,#TIMERVAL40K ;LOAD TIMER0

CLRB TIMERFLAG ;CLEAR TIMER0 OVERFLOW FLAG

JB XMIT1,RTB ;TEST PRESENT O/P STATE

NOP

MOV RA,#XMITA ;FLIP O/P STATE

JMP RTC

RTB MOV RA,#XMITB ;FLIP O/P STATE

RTC DJNZ COUNTER1,RTA ;CYCLE AGAIN?

MOV RA,#XMITLOW ;PULL DOWN BOTH SIDES OF TRANSMITTER

;CALL MINRETURN ;RUN SHORT DELAY

;CALL XMITOFF ;DISABLE TRANSMITTER DRIVER PINS

;CALL MINRETURN ;RUN SHORT DELAY

CALL WORDDELAY ;MAYBE REMOVE THIS LATER

; CLR TEMP

;RTG JB DETECT,RTF ;TEST FOR START OF VALID RANGE

; CALL RANGETICK

; DJNZ TEMP,RTG

RTF CLR TEMP ;CLEAR RANGING ACCUMULATOR

RTD JNB DETECT,SEERETURN;SEE A RETURN YET?

CALL RANGETICK ;RUN SHORT DELAY BETWEEN RANGE INCREMENTS

ADD TEMP,#1

JNZ RTD ;CHECK FOR OVER-RANGE

JNC SEERETURN ;CHECK FOR MAX-RANGE

DEC TEMP ;SET TO MAX RANGE

SEERETURN MOV RANGERESULT,TEMP;SAVE TEST RESULT

MOV COUNTER1,TEMP ;RUN A DELAY WHICH FILLS IN THE REST

NOT COUNTER1 ; OF THE TIME A MAX RANGE HIT TAKES.

JZ RTDONE

RTE CALL RANGETICK

DJNZ COUNTER1,RTE

RTDONE RET

;----------------------------------------------------------------------------

;RANGEAVER:AVERAGES RESULTS OF 8 TESTS BEFORE UPDATING RANGEAVER VALUE

RANGEAVER ADD RANGEDATAL,RANGERESULT

SNC

INC RANGEDATAH

DJNZ RESULTCOUNTER,RANGEAVEREND

RR RANGEDATAH

RR RANGEDATAL

RR RANGEDATAH

RR RANGEDATAL

RR RANGEDATAH

RR RANGEDATAL

RR RANGEDATAH

RR RANGEDATAL

MOV RANGEAVERAGE,RANGEDATAL

CLR RANGEDATAL

CLR RANGEDATAH

MOV RESULTCOUNTER,#8

RANGEAVEREND RET

;----------------------------------------------------------------------------

;MINRETURN:TIME FOR SOUND TO TRAVEL 6" OUT AND 6" BACK = 885us

;(SPEED OF SOUND 13560"/s)

MINRETURN MOV DELAYCOUNTER2,#6

MRA MOV DELAYCOUNTER1,#244

DJNZ DELAYCOUNTER1,$

DJNZ DELAYCOUNTER2,MRA

RET

;;----------------------------------------------------------------------------

;;RANGETICK:TIME FOR SOUND TO TRAVEL MAXIMUM RANGE (24') / 255 = 139us

;;(SPEED OF SOUND 13560"/s)

;RANGETICK MOV DELAYCOUNTER1,#229 ;VALUE WAS 230, BUT THIS IS

; ;ADJUSTED TO COMPENSATE FOR

; ;SURROUNDING INSTRUCTIONS IN LOOP

; ;WHICH CALLS THIS ROUTINE.

; DJNZ DELAYCOUNTER1,$

; RET

;;----------------------------------------------------------------------------

;RANGETICK:TIME FOR SOUND TO TRAVEL MAXIMUM RANGE (??') / 255 = ???us

;(SPEED OF SOUND 13560"/s)

RANGETICK MOV DELAYCOUNTER1,#50

DJNZ DELAYCOUNTER1,$

RET

;----------------------------------------------------------------------------

;XMITON:ENABLES TRANSMITTER DRIVERS

XMITON SETB RP0 ;SET RP0 TO UPPER REGISTER BANK

MOV RA,#XMITENABLE

CLRB RP0 ;SET RP0 TO LOWER REGISTER BANK

RET

;----------------------------------------------------------------------------

;XMITOFF:DISABLES TRANSMITTER DRIVERS

XMITOFF SETB RP0 ;SET RP0 TO UPPER REGISTER BANK

MOV RA,#XMITDISABLE

CLRB RP0 ;SET RP0 TO LOWER REGISTER BANK

RET

;----------------------------------------------------------------------------

READTABLE MOV PCLATH,#LCDMESSAGES< ;TABLE = LCDMESSAGES

MOV W,TABLEENTRY

CALL LCDMESSAGES ;READ TABLE FROM LOCATION MESSAGE# ADDR

;CLRB PCLATH.3

CLR PCLATH

MOV TABLEVALUE,W

RET

;----------------------------------------------------------------------------

ORG 03E1H

LCDMESSAGES JMP PC+W ;Mess#

RETW '0','1','2','3','4','5','6','7','8','9';E0-9 1

RETW 'S','o','n','a','r','1',' ',' ',' ',' ';E10-19 2

RETW 'r','a','n','g','e',':',' ','-','-','-';E20-29 3

;----------------------------------------------------------------------------

;END OF LISTING

Mechanical ranging is old news, but it is seldom done really well. Here are a couple "better" ideas.

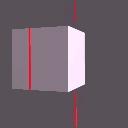

Bumpers don't

give enough warning because they are generally simple on/off things that

don't stick out very far. One of the most brilliant things I've ever seen

was the design of a "sane" car that had a huge spring "bumper" that looped

out in front of the car and extended a little out to each side. The attachment

points on either side were hinged and then extended so that they crossed

under the car. At that point, they intersected a "joystick" which ran up

to the driver through a ball joint. I've drawn up a little picture and the

red dot is the joystick. The left and right edges of the spring have rollers

which are designed to follow a special curb at either side of each lane.

When they are "squeezed" the result is that the stick is pushed forward,

increasing the speed of the car. Contact with the front of the spring pulls

the stick back, slowing the vehicle. Any misalignment of left to right pressure

causes the car to steer to a corrective course and thereby follow the "curbs."

Dead simple, hopefully reliable, and... proportional. It was designed

by a little girl for her science fare entry and I've never been able to forget

it. I wish I knew where she ended up.

Bumpers don't

give enough warning because they are generally simple on/off things that

don't stick out very far. One of the most brilliant things I've ever seen

was the design of a "sane" car that had a huge spring "bumper" that looped

out in front of the car and extended a little out to each side. The attachment

points on either side were hinged and then extended so that they crossed

under the car. At that point, they intersected a "joystick" which ran up

to the driver through a ball joint. I've drawn up a little picture and the

red dot is the joystick. The left and right edges of the spring have rollers

which are designed to follow a special curb at either side of each lane.

When they are "squeezed" the result is that the stick is pushed forward,

increasing the speed of the car. Contact with the front of the spring pulls

the stick back, slowing the vehicle. Any misalignment of left to right pressure

causes the car to steer to a corrective course and thereby follow the "curbs."

Dead simple, hopefully reliable, and... proportional. It was designed

by a little girl for her science fare entry and I've never been able to forget

it. I wish I knew where she ended up.

For smaller applications, the connection points can be pots or other rotary encoders. The difference between the readings indicates front/back contact. The addition of the readings is proportional to the amount of left/right contact.

Huh? The idea here is to throw some small object and see if it bounces back. Won't that mess up the area? Not if you throw particles of the environment around you. "Throw" air. Look for the returning breeze. Or water, sand, etc... This is the same method that gives you that weird sense of solid objects close by when you are not able to see and the hair on your face or arms pick up the little currents of air that are bounding off the wall you will walk into just before you have time to stop. This is heightened the more skin exposed and can be quite accurate when leaving a pitch dark house out the back door without ones clothes. Don't ask.

It was first suggested to me by one of the few ladies on the PICList but the only implementation of this I have ever seen was an entry in a robot "firefighter" competition by an obviously brilliant engineer. He (sorry girls, it was a he) started off with the fact that the candle needed to be blown out. Rather than depend on accurate positioning, he realized that he could just "spit" air in all directions at the given height of the candle. So he mounted a whisper fan vertically and found an inverted cone-like baffle that would direct the air to all sides. After setting that up, he realized that the air from the top was being circulated back to the bottom faster when the bot was up near a wall. His bumpers became nothing more than flags and never contacted anything under normal operation. When he ran the 'bot we realized that another advantage of the proportional sensing of wall proximity allowed him to go much faster and round the corners without slowing down because he had some room between first sensing the wall and actually hitting it. The 'bot had no brains to speak of, it just turned away from any flag that dropped down. Sadly, the rules of the competition didn't allow the 'bot to just blow out the candle and keep going; the judges ruled that it had to actually sense the flame and this 'bot never had that ability! He did put out the candle faster than anyone else, just about every run.

See also:

Also known as a stud sensor. Good for short range sensing. They need to be

re-calibrated constantly so you need some other way of knowing that nothing

is in the area at all. I know of two versions:

By GB Instruments

and available at Home Depot for about $10 again. One 8 pin 555 timer chip

connected to the antenna. The second 8 pin chip is a PIC chip, maybe a 12c508.

The 555 outputs a pulse stream. As an object moves toward the antenna the

width of the pulses lengthened. Looks like the PIC chip simply calibrates

the pulse width on startup, and if the pulse width stretched beyond a threshold

,say 40%, it turns on an LED. Can't get much simpler than that.

By GB Instruments

and available at Home Depot for about $10 again. One 8 pin 555 timer chip

connected to the antenna. The second 8 pin chip is a PIC chip, maybe a 12c508.

The 555 outputs a pulse stream. As an object moves toward the antenna the

width of the pulses lengthened. Looks like the PIC chip simply calibrates

the pulse width on startup, and if the pulse width stretched beyond a threshold

,say 40%, it turns on an LED. Can't get much simpler than that.

In a word, unreliable except under very controlled conditions. They get used in bathrooms all the time to flush the toilets and turn on the sinks. In a nice SoCal restaurant, while exporting the byproduct of processing my pre-dinner drink, I kept hearing a sink turning on and off. On the way out I saw why: A high window was allowing sunlight to fall just on the inside of the sink at about the point that the sensor was looking. It would warm up, the sink would turn on, the water spray was enough to cool the sink and turn the water off again. Anyone who has used a TV remote from any distance should realize that IR is NOT a viable technology. If you must, see also:

| file: /Techref/new/letter/news0310.htm, 43KB, , updated: 2024/1/22 19:33, local time: 2025/10/24 08:29,

216.73.216.20,10-1-5-169:LOG IN

|

| ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions? <A HREF="http://massmind.ecomorder.com/techref/new/letter/news0310.htm"> October 2003 MassMind Newsletter</A> |

| Did you find what you needed? |

Welcome to ecomorder.com! |

Welcome to massmind.ecomorder.com! |

.